Most of the slaughter blood generated in the slaughter process of cattle, pigs, etc. is thrown away and it is necessary to spend a lot of money for facility investment and operation for water treatment. By turning it into a resource, not only can the added value be increased, but also the cost of water treatment can be reduced and the environment can be improved.

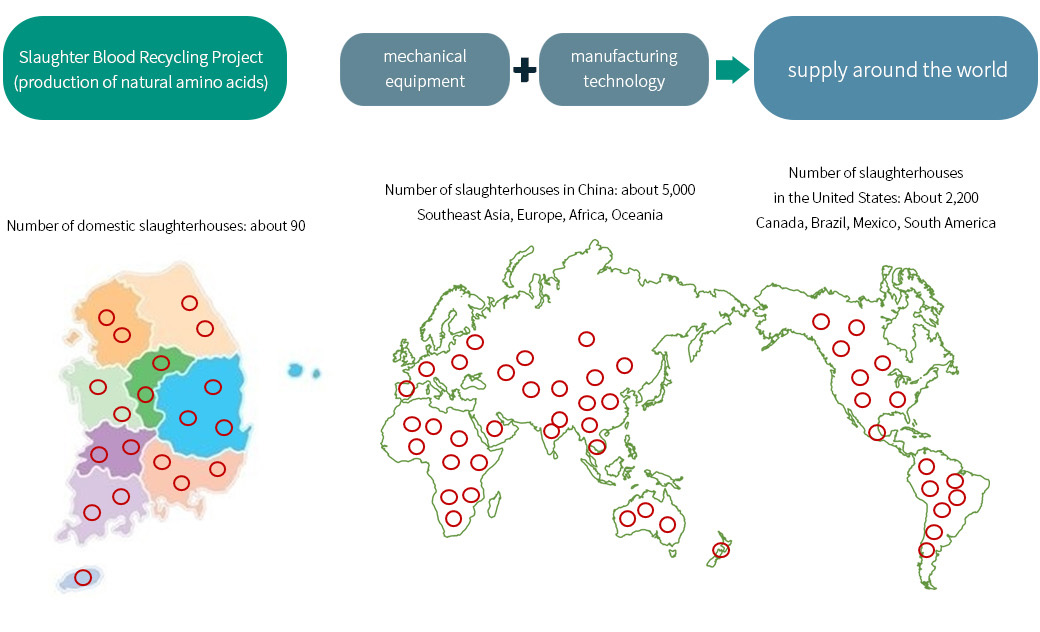

About 80,000 tons/year of slaughtered blood is generated in Urana, and a huge amount of slaughtered blood is generated around the world, about 15 million tons/year, but the rate of use of this in industry is very small and most of it is disposed of.

With a budget of 1.2 billion won from the Ministry of Agriculture, Food and Rural Affairs, our company completed the development of natural anminoic acid mass production technology using slaughtered blood protein after 3 years of R&D with master's and doctoral professionals such as Korea Testing Laboratory and Seoul National University. We are running a business meeting.

This technology is an advanced technology in the world, and it is a state-of-the-art technology that produces more than 95% of protein from slaughtered blood with natural amino acids within one hour. The produced natural amino acids are used in various businesses such as eco-friendly fertilizers, feed, food, and cosmetics.